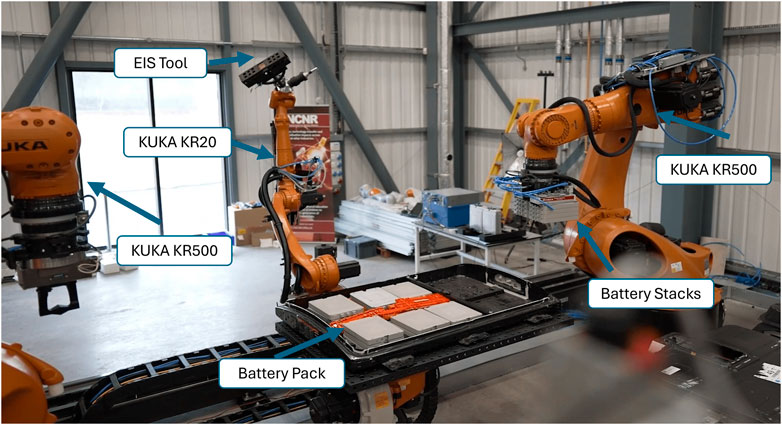

We developed a robotic workflow that automates electrochemical impedance spectroscopy (EIS) for electric vehicle batteries. A KUKA KR20 mounted on a 5 m rail cooperates with a custom end-of-arm potentiostat to deliver repeatable connections, measure impedance spectra, and let human operators intervene whenever necessary.

System Highlights

- Shared autonomy allows the robot to operate fully automatically yet hand control back to an operator through an admittance controller for delicate alignment.

- Force/torque sensing safeguards connections, while the rail extends the work envelope to handle packs of varying size.

- Finite element analysis validated the structural rigidity of the custom end-of-arm tooling.

Results

- The platform differentiated battery modules with degradation levels up to 1.5 mOhm internal resistance.

- Automated procedures reduced human exposure to high-voltage components and improved repeatability over manual probes.

- The workflow scales to production thanks to modular design and rapid reconfiguration for new pack architectures.