This is a simulation of a workcell focusing on assembling a piece, made up of a lid and a base. The conveyor bands work in an asynchronous manner, so sensors must be used and programmed to determine the correct time the lid should be picked and placed on the base. A counter of the amount of items assembled is also part of the workcell. The amount of pieces can be limited just by changing a variable in the program, and the process can be stopped in case of an emergency. If no problem arises the process may continue indefinitely. This cell was programmed both with FactoryIO FBD and with the LOGO! FBD.

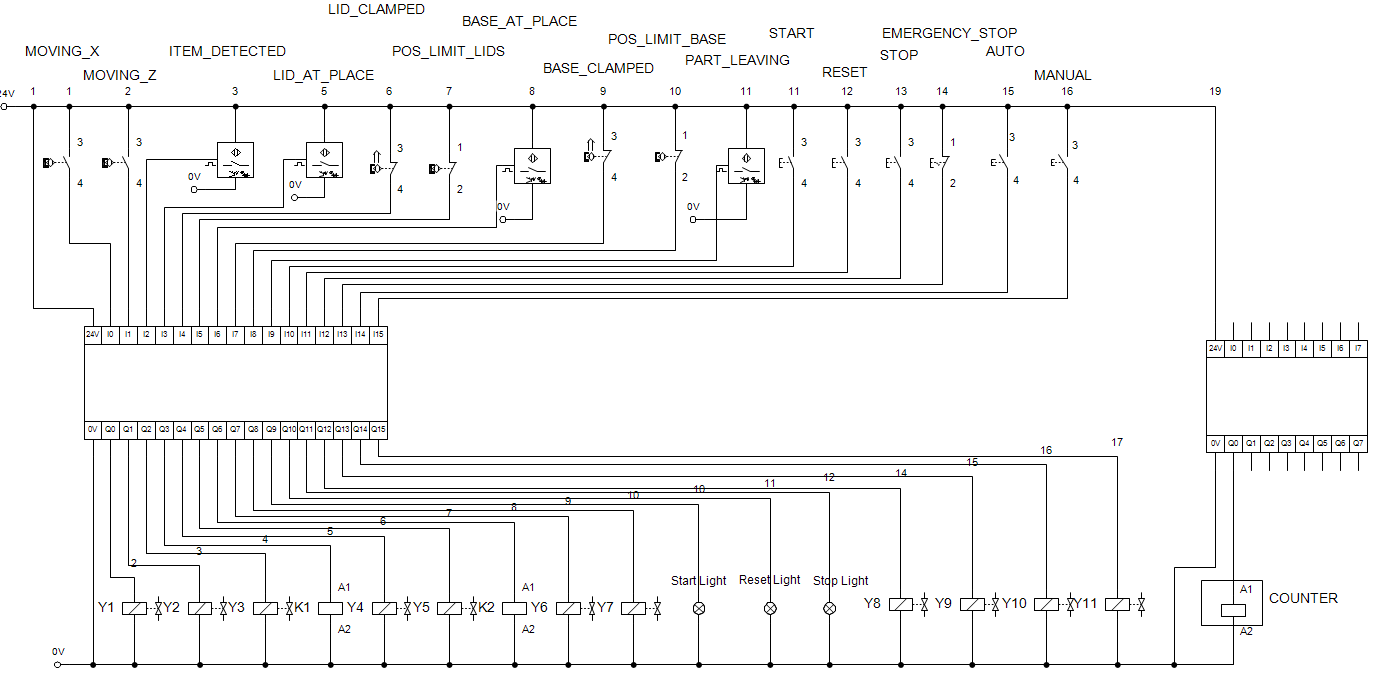

Connections Diagram

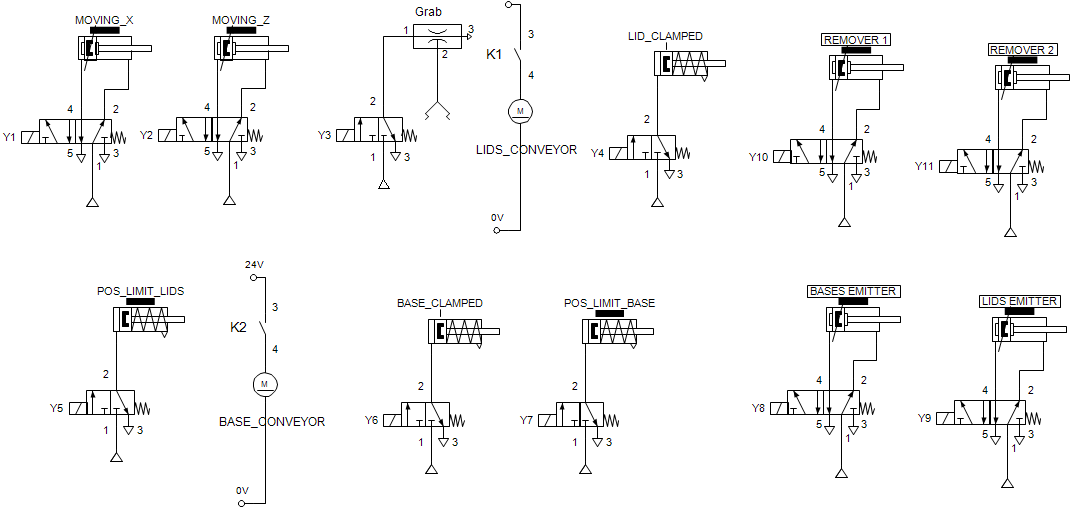

Actuators Diagram

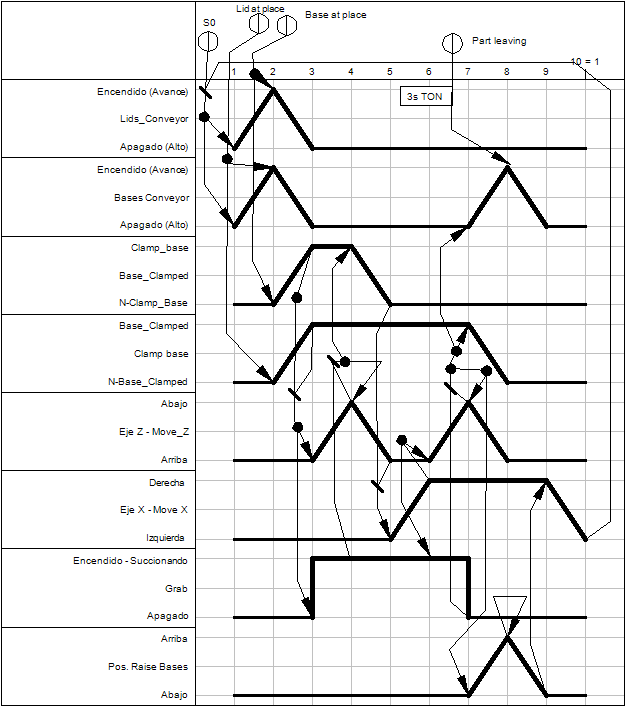

Movement Diagram

FBD Inputs and Outputs from the scene

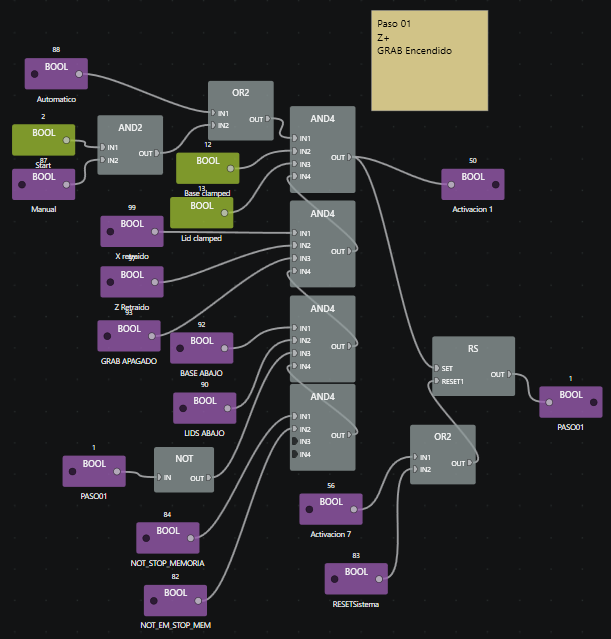

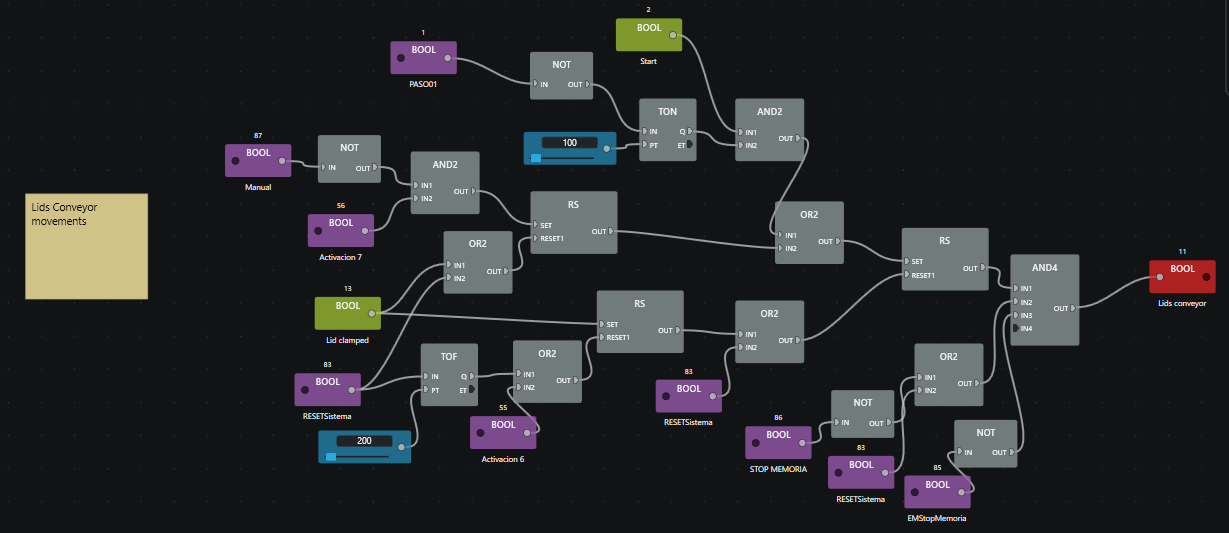

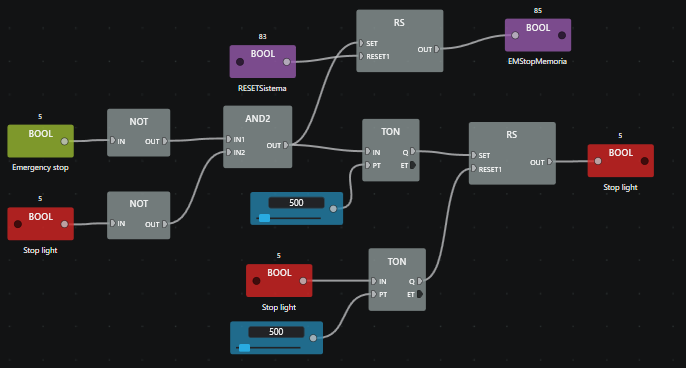

FactoryIO FBD Code Example

STEP 1

LIDS Conveyor

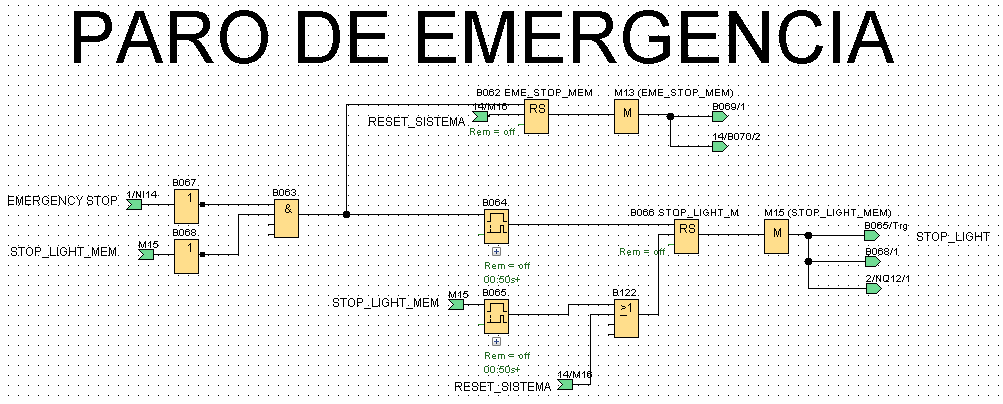

Emergency Stop

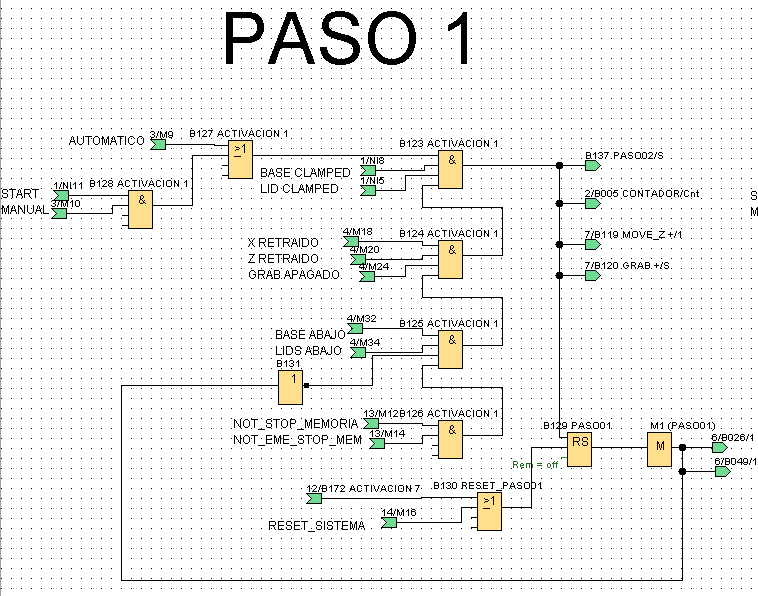

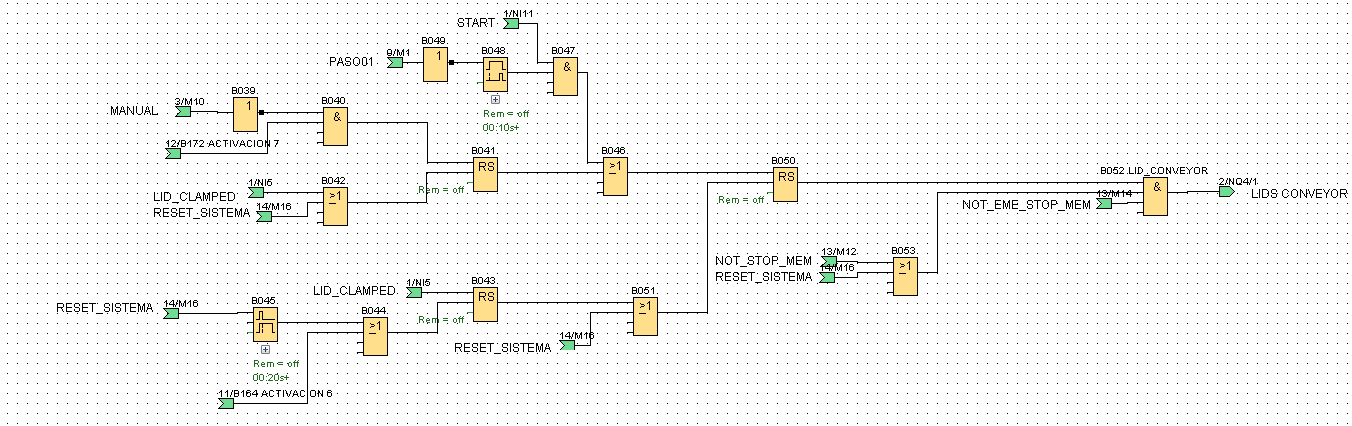

LOGO! FBD Code Example

STEP 1

LIDS Conveyor

Emergency Stop

PREVIOUSPick & Place XYZ